DSI Thin Film Coating Technologies

An optical thin film consists of one or more layers of dielectric material or metal, with individual layer thicknesses typically ranging from a few nanometers to several microns. In the case of dielectrics, these modify the reflectance and transmittance characteristics of the underlying substrate through the mechanism of optical interference, based on the exact thickness

Photolithography Technology

The drive towards smaller sensors, often integrated on monolithic substrates with other processing electronics, has created a need for coatings directly on semiconductor wafers, or on miniaturized substrates that can readily be assembled with active devices. DSI utilizes photolithography to produce a wide array of precision patterned thin film coatings (such as antireflection coatings, bandpass filters, dark mirrors, and metals), with feature sizes as small as 5 µm, on substrates up to 8 inches in diameter.

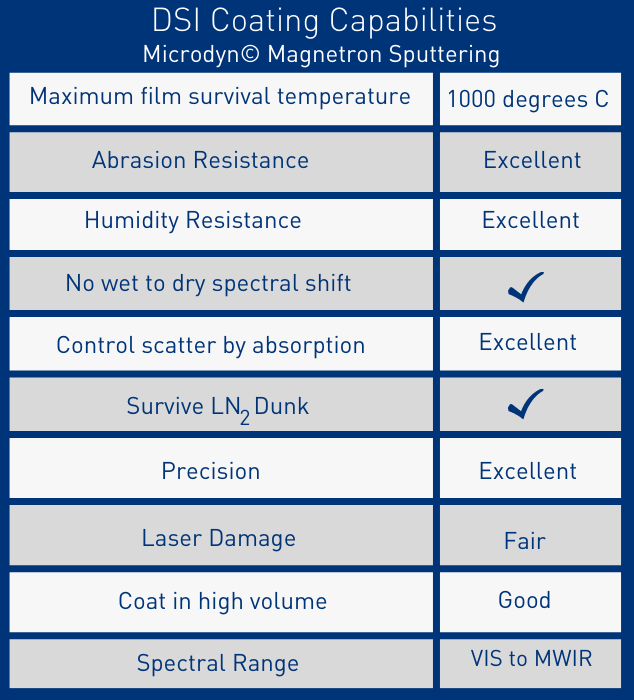

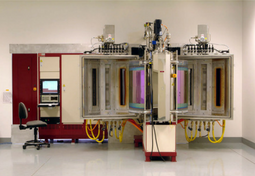

MicroDyn® Technology

MicroDyn® is DSI’s proprietary version of magnetron sputtering optimized for high throughput. MicroDyn® utilizes an octagonally shaped chamber, where electrically conductive (metal or semiconductor) coating targets are arranged around the periphery, and the parts to be coated are held on a cylindrical rotating drum concentric within the chamber. Unlike other optical coating methods, sputtering does not require heating the coated parts. This allows the technique to be used on a wide range of substrate materials, as well as on assemblies that may incorporate plastic parts.

COATING TECHNOLOGY ENABLES EFFECTIVE MISSILE COUNTERMEASURES

Infrared countermeasures often require high performing optical coatings, but operating extremes pose a challenge to manufacturers. Read how the DSI team uses proprietary technology and