PRODUCT OVERVIEW

Notch filters block a range of wavelengths while transmitting both shorter and longer wavelengths outside of the blocked region. Thus, they provide the exact opposite functionality of a bandpass filter. One of the most common uses of DSI notch filters is in thermal infrared imaging systems where they are used to block the atmospheric CO2 absorption band (at about 4 µm). Otherwise, atmospheric absorption of this wavelength creates a highly distance-dependent variation in the measured infrared signal which can lead to measurement error. Another major application for DSI notch filters is in eyewear to block laser emissions for military, medical and industrial applications.

THE DSI DIFFERENCE

DSI has extensive experience in the design and manufacture of notch filters for use at wavelengths ranging from the ultraviolet through the long-wave infrared. These include broad and narrow notch designs. All DSI notch filters are characterized by high in-band blocking, excellent out of band transmission and immunity to shifts due to changing humidity.

DSI NOTCH FILTER ADVANTAGES

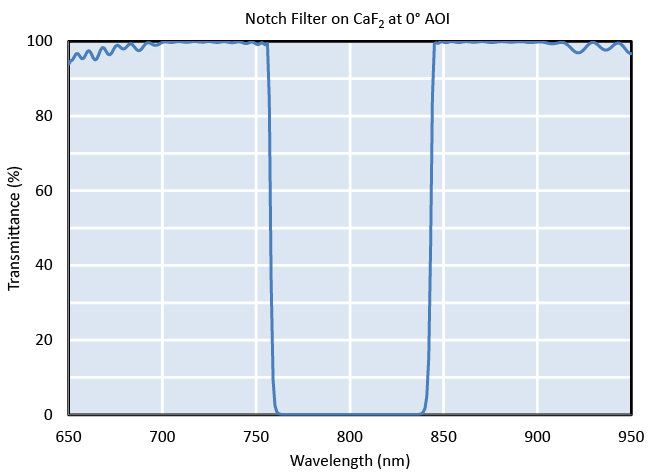

- High in-band rejection

- Sharp cut-on/cut-off slopes

- Excellent out-of-band transmission

- No wet/dry wavelength shift

DSI ABSORPTION COATING APPLICATIONS

- Military defensive goggles

- Military targeting and tracking

- Laser eye protection

Contact Us For More Information

TECHNICAL INFORMATION

For the buyer of notch filters, it’s useful to understand some of the most common design and production tradeoffs in order to avoid writing specifications in a way that drive up cost unnecessarily.

WAVELENGTH ACCURACY VS. COST

Tight tolerances (below ±0.5%) on center wavelength or edge placement can lower yield and thus adversely impact price. While extremely tight tolerances for these values can be achieved by measuring and selecting filters after fabrication, this can become expensive as part size increases, and may not be entirely practical in higher volumes.

ANGLE AND TEMPERATURE SENSITIVITY

The spectral characteristics of all optical coatings shift to shorter wavelengths as angle of incidence is increased, and/or temperature is decreased, and this can dramatically affect the performance of notch filters. In some cases, this effect can be purposefully employed to enable tuning of the filter’s performance over a limited range of wavelengths

Download the Datasheet

SPECTRAL CURVE