Product Overview

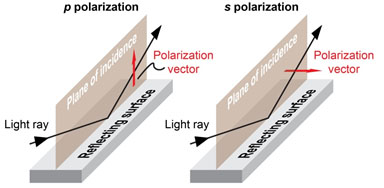

A plate beamsplitter is a planar optic used to divide incoming light into reflected and transmitted components with a specified, constant intensity ratio over a given wavelength range (see Dichroic Beamsplitters for optics whose transmittance/reflectance properties are wavelength dependent). Polarizing beamsplitters are similar devices that perform this function based on the polarization state of the input light.

The DSI Difference

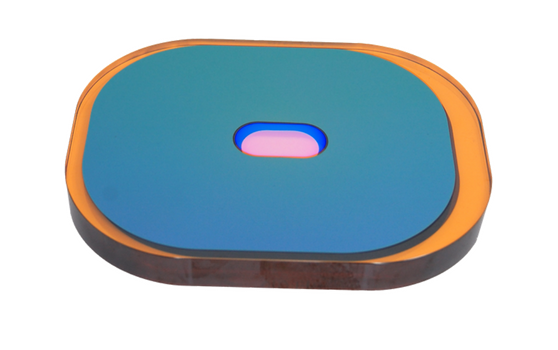

DSI custom manufactures a wide variety of plate type beamsplitters, including polarizing and non-polarizing designs, for use in the ultraviolet, visible, and infrared spectral regions. We can deliver beamsplitters for use at non-zero angles of incidence which are largely insensitive to polarization, as well as polarizing beamsplitters with high extinction ratios. We also excel at producing beamsplitters for broadband use throughout the infrared.

Technical Information

When specifying beamsplitters, it is important to note the angle of incidence of intended use, and the state of polarization (s, p, or unpolarized) of the incident light.

We use MicroDyn® magnetron sputtering coating technologies for fabricating these products, depending on the substrate characteristics and performance specifics. Beamsplitter coatings are typically applied to the first surface of the part, while an AR coating is placed on the second surface. AR coatings usually have fewer layers than the beamsplitter coating, and because optical thin films are typically in compressive stress, this thickness difference can degrade the surface figure for thinner optics. To address this, DSI can add layers to the antireflection coating which changes its mechanical stress characteristics without altering its spectral performance.

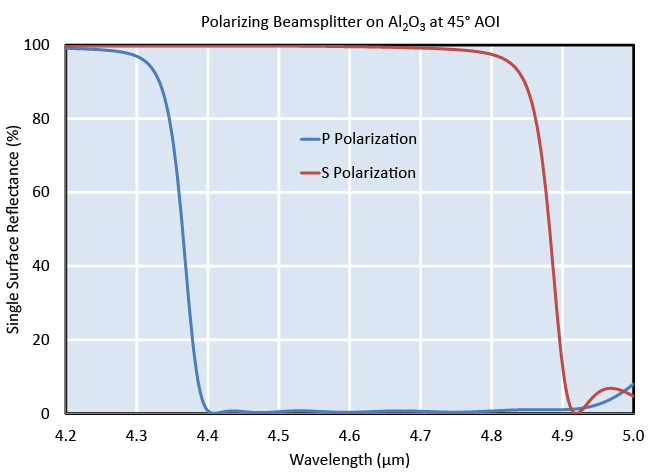

Spectral Curve

Polarizing Beamsplitter on Al2O3 at 45° AOI: